Preventing Costly Shipment Errors

Amazon's Seller Central

My Role

UX Designer

Team Compilation

UX Manager, Product Manager, Development

Duration

9 Months (End-to-End Design)

Overview

Amazon’s Seller Central platform allows third-party sellers to list and ship products through Send to Amazon, a tool that helps sellers inbound inventory to Amazon warehouses. However, sellers frequently fail to follow Amazon’s shipping guidelines, leading to shipment defects. These defects negatively impact sellers’ shipment performance, and severe violations can result in account suspension and lost sales opportunities.

On a broader scale, Amazon estimated that seller-related defects—including inventory and shipping compliance issues—would cost $4.4 billion in 2024 without intervention. To address this, the Jedi initiative was introduced to provide sellers with real-time, contextual assistance during shipment creation, reducing defects and ensuring compliance.

Problem & Goal

Many sellers struggle to comply with Amazon’s shipping requirements, leading to costly shipment defects. The goal of this project was to:

- Reduce shipment defects by providing sellers with real-time guidance within the Send to Amazon workflow.

- Minimize compliance-related costs, estimated to grow to $4.4B, by preventing errors before shipments arrive at Amazon’s warehouses.

- Improve seller onboarding and education, particularly for:

- New sellers (≤6 months experience) who struggle with learning Amazon’s shipment guidelines.

- High-defect sellers (≥1 year experience) who have established habits but want to optimize their operations.

- New sellers (≤6 months experience) who struggle with learning Amazon’s shipment guidelines.

By addressing these challenges, Amazon could save an estimated $1.6 billion over the next three years by reducing shipment errors and compliance costs.

Design Process

Establishing the North Star Vision

Through research, we found that sellers who receive 1:1 coaching reduce shipment defects by up to 40%, but scaling this support was not feasible. To automate assistance, I conducted a competitive analysis of UI conversational design and mapped out defect scenarios across the shipment workflow.

Concept Development & Prototyping

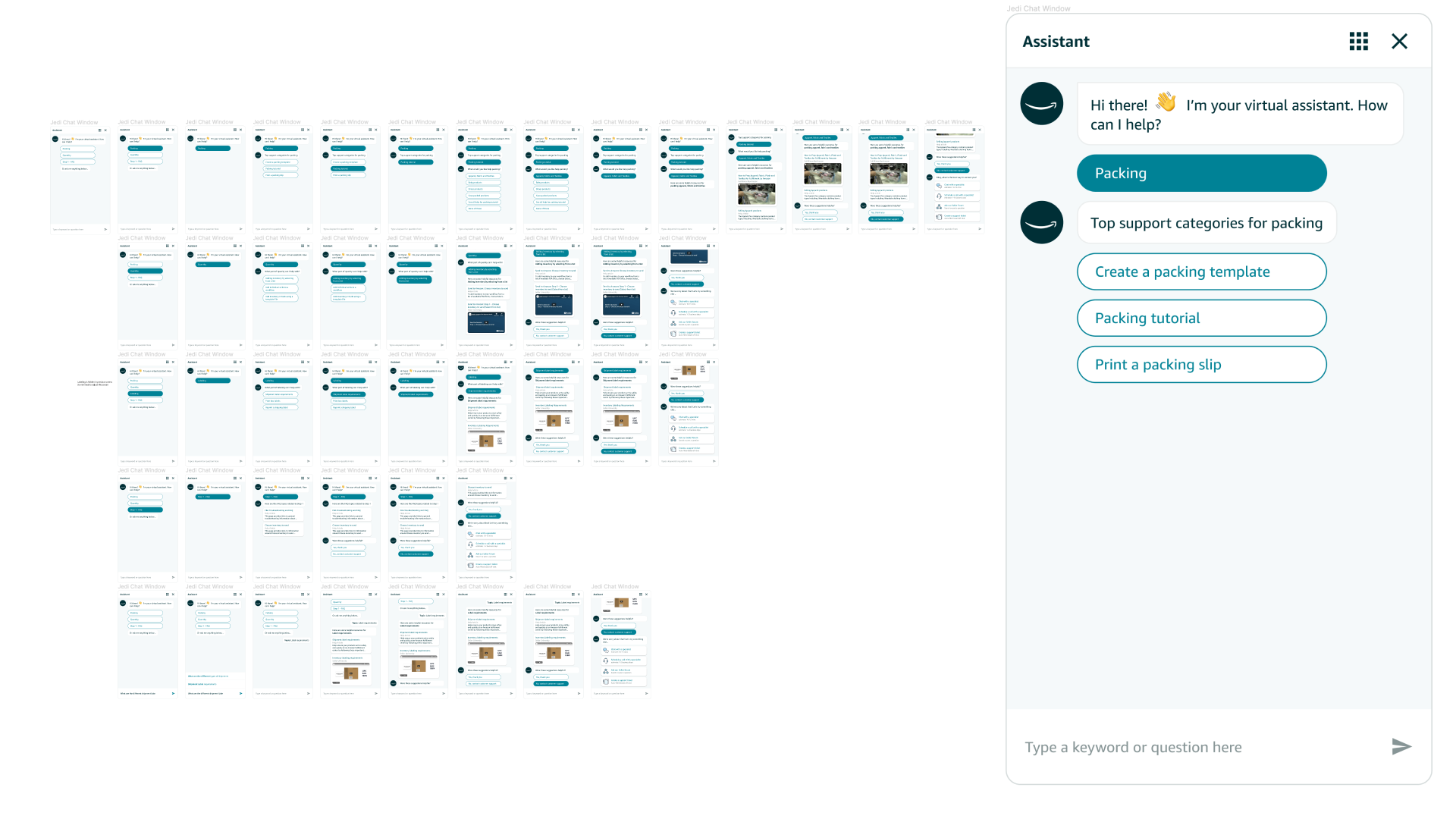

Based on these insights, I designed a prototype that:

- Introduced an AI-driven assistant using a rule-based conversational model to guide sellers.

- Provided real-time contextual alerts when sellers made common shipment mistakes.

- Referenced historical shipment defects so sellers could see how issues impacted their performance.

Through user testing, sellers responded positively, particularly to automated alerts that surfaced issues before shipment creation was completed:

“…when you could have an issue just pop up right here that alerts you and tells you if there’s something wrong—that would be a game changer. Honestly, because it takes manual work out of it.”

Refining for Phase 0 Implementation

Given technical constraints, machine learning models and real-time contextual alerts were not feasible for the initial release. Instead, we implemented a rule-based system to onboard specific defect types, starting with Carton Overweight Defects (when a shipment exceeds 50 lbs).

Key design challenges included:

- When to alert sellers during shipment creation.

- How to present defect information without overwhelming users.

User Testing & Iteration

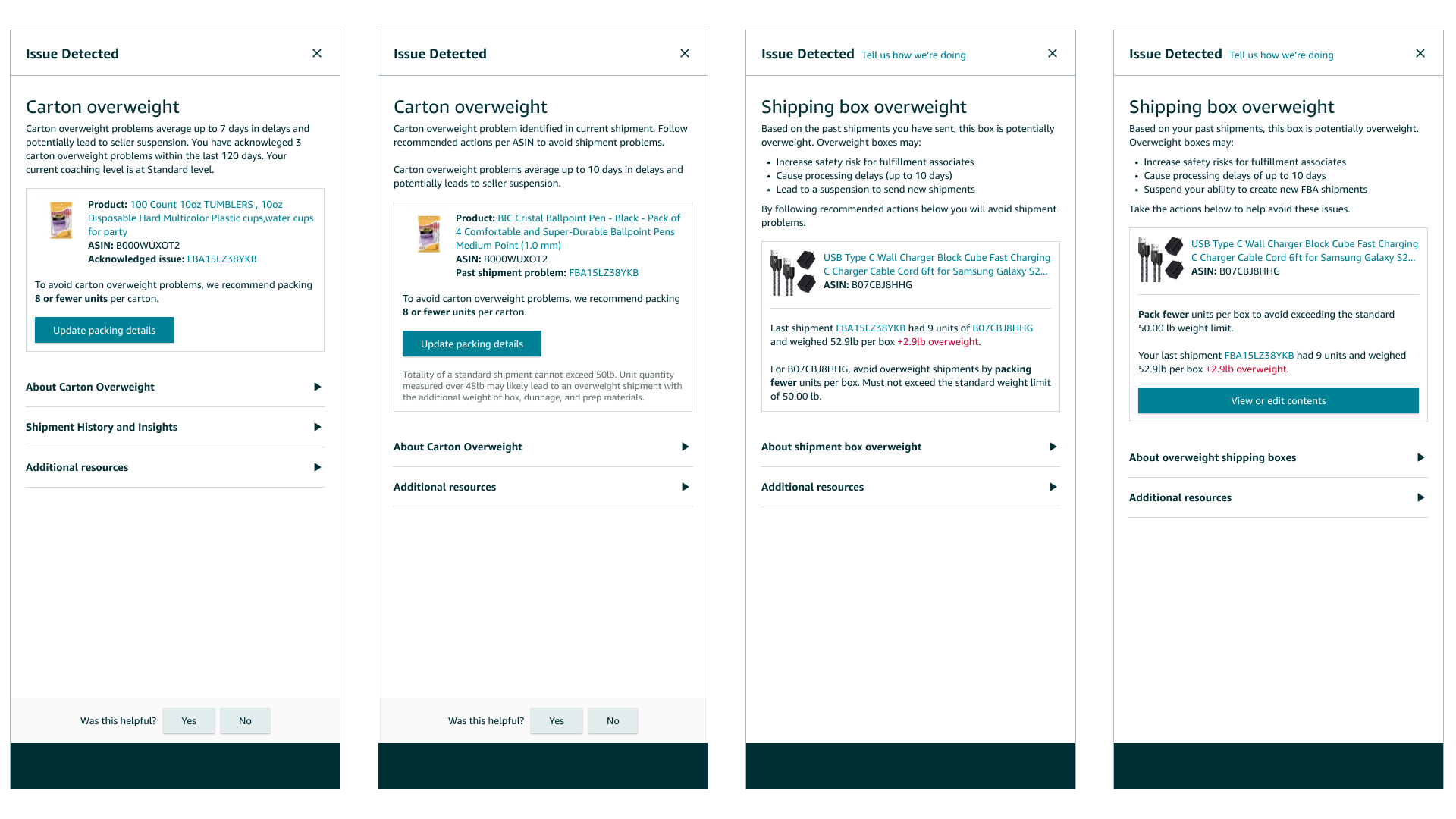

Through multiple design iterations and user testing, I optimized the defect alert system by:

- Clarifying defect details (problem, impacted product, and necessary corrective actions).

- Providing shipment history and insights so sellers could understand why the issue occurred.

- Adding an "Additional Resources" section for deeper learning.

Solution & Results

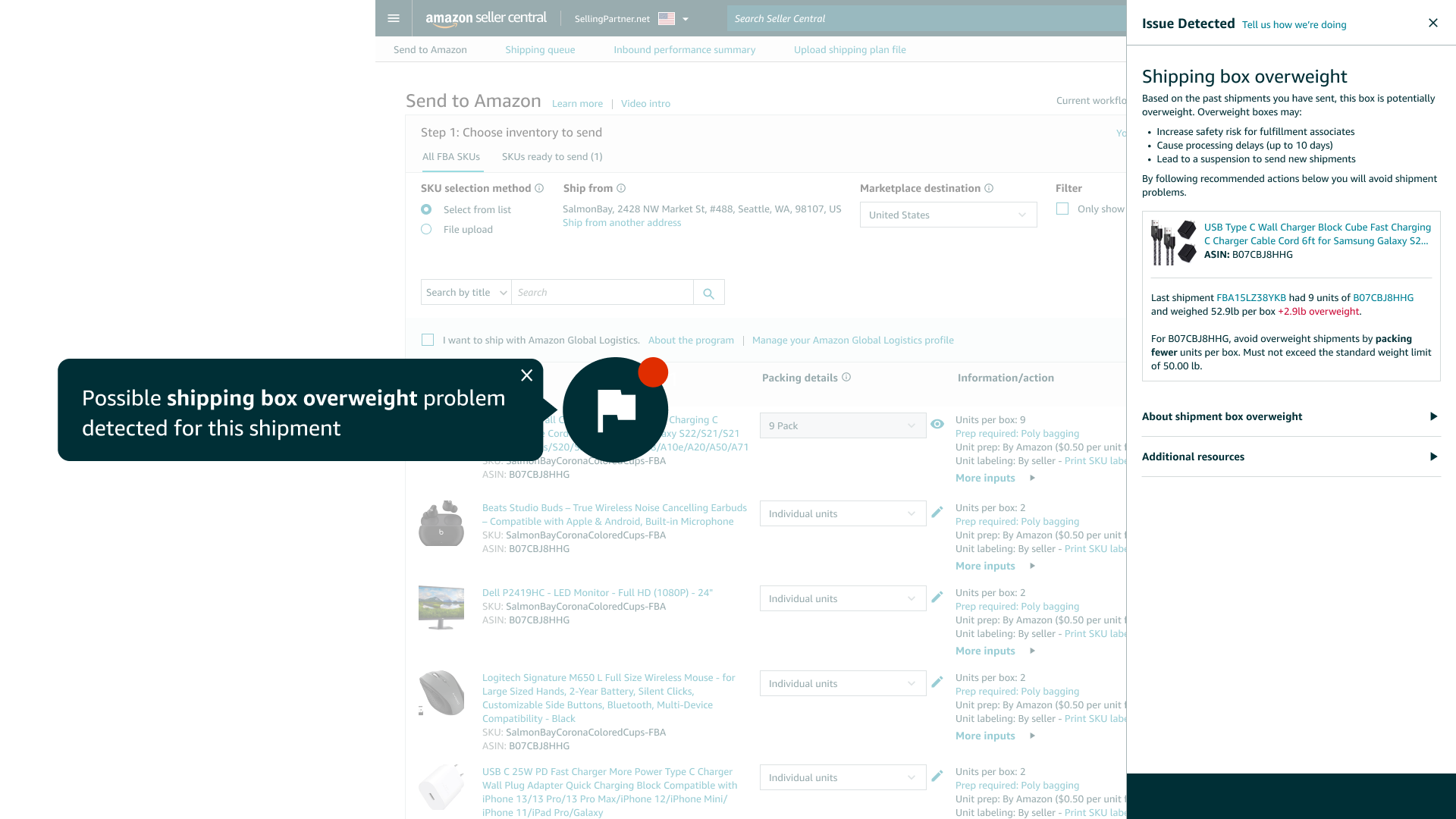

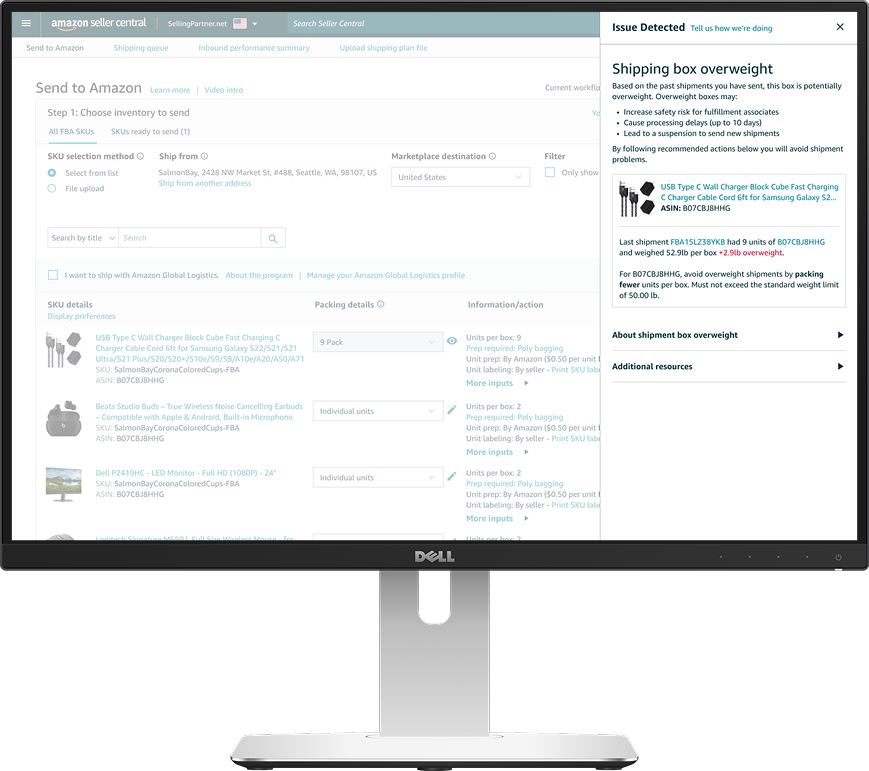

For the Phase 0 launch, we implemented a streamlined defect alert system that:

- Appears in the bottom-right corner during shipment creation.

- Informs sellers of the defect type, impacted product, and corrective actions.

- Provides access to detailed resources and past defect history.

Impact

- $100K in cost savings at launch.

- Projected $100M in savings for 2023 as more defect types are onboarded.

Reflections & Future Improvements

While the Phase 0 launch was a success, there are opportunities for continued improvement:

- Expand defect coverage beyond Carton Overweight to other common compliance issues.

- Introduce machine learning models to improve accuracy and automation in defect detection.

- Enhance seller education tools by adding interactive learning experiences.

By iterating on this foundation, Amazon can continue to drive compliance, reduce costs, and improve the seller experience within Seller Central.